Hammer mill is an efficient and multifunctional equipment, with good fineness, high quality and high efficiency. It is widely used in the production industries of wood, straw, fertilizer, pellet fuels, animal bedding and feeding, biomass coupled power plant, biogas power generation, biomass fuel, paper mill, etc.

Hammer mill uses a high-speed rotating rotor to quickly crush materials, and its large body and droplet shaped design improve production efficiency and reduce circulation. The motor drives the rotor to rotate at high speed in the grinding chamber. The material is fed in from the upper feed port and is hit and impacted by the high-speed rotating hammers, gradually becoming small particles. Under the action of centrifugal force and airflow, the smaller particles are discharged through the screen, while the larger particles remain in the screen and continue to be hit and crushed by the hammers. It is an indispensable equipment in modern industrial production that can meet different particle size requirements by adjusting the screen size.

Rice husk, rice straw, corn cobs, tree bark, leaves, wood chips from logs, branches, pallets, waste boards, wooden strips, bamboo,etc.

Wood Chips

Rice Husk

Rice Straw

Corn Cob

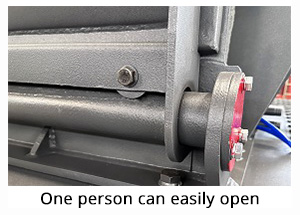

1. Fully open operating door for easy operation and maintenance.

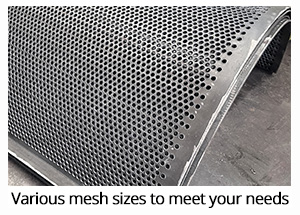

2. Quick-detachable screen, U-shaped wrapping design, a variety of screen mesh specifications are available, mesh fineness can reach 3 mm.

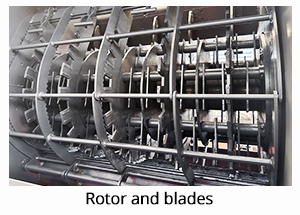

3. Built-in rotor, specially designed with two different hammer-screen gaps, which can meet the requirements of coarse/fine grinding. Scientific and reasonable hammer arrangement, running smoothly and the finished product has uniform fineness.

4. Manganese steel blade, hardened manganese steel, wear-resistant and impact-resistant.

5. The integral base design makes the whole machine stable, the parts welded with international standard steel plates improve the structural strength and extend the service life.

Kowloon Machinery has 19 years of technology accumulation and specializes in the production of solid waste recycling equipment, such as waste tires, scrap metals, biomass waste, wood waste, MSW waste, industrial waste, agricultural and forestry waste, etc., A variety of models for you to choose, we also provide free customized solutions based on your needs. Our products have obtained multiple patents and CE, ISO certifications. At present, our solid waste recycling projects cover Poland, Czech Republic, Romania, Russia, South Africa, Algeria, Zambia, Turkey, Saudi Arabia, Thailand, Malaysia, Pakistan, Bangladesh, Brazil, Canada and many other countries. Looking forward to cooperating with you! Consult us now!