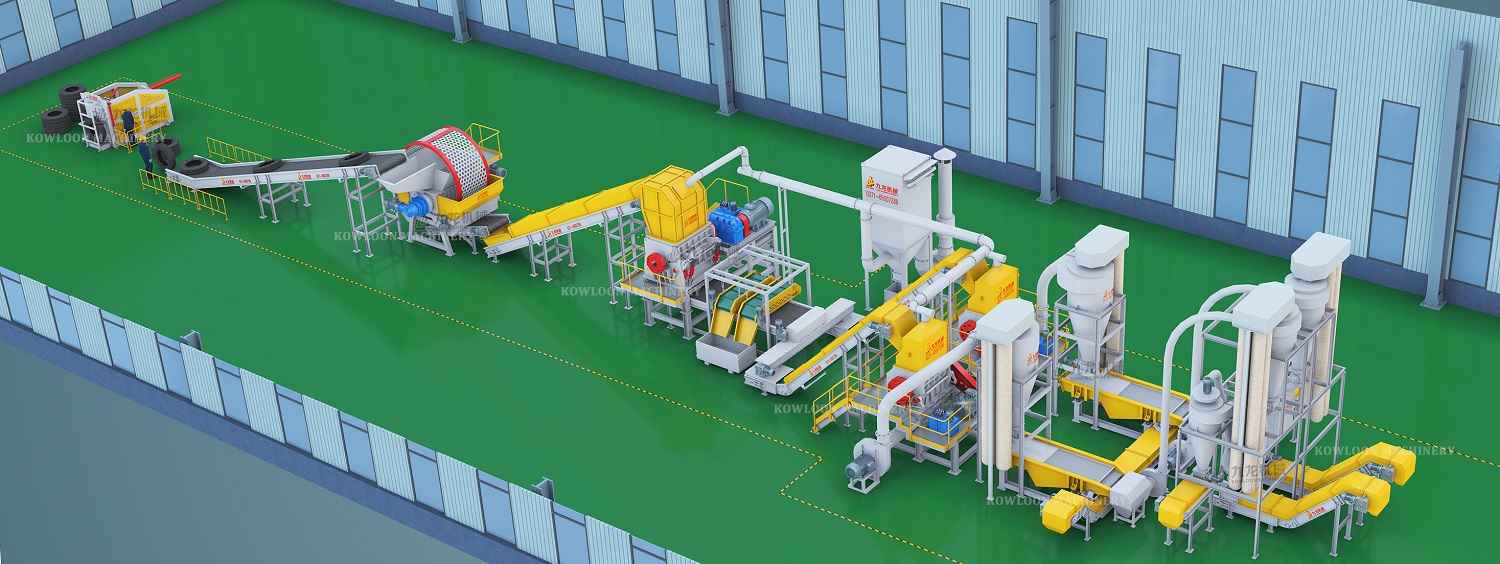

Through the whole process of intelligent automation, waste tires resource system realizes the high-value recycling of tires: the tire bead wires are precisely stripped with a tire debeader. Tires are crushed into 50-100mm by a double-shaft shredder, and then crushed into 10-20mm by a rubber rasper. The residual wire is completely separated by bipolar magnetic separations. Furthermore, the crushed rubber is processed into 1-7mm by a rubber granulator or 5-80 mesh by a grinder. There is ladder type air separator to remove fiber impurities, and a pulse dust removal system to achieve clean production.the entire system is monitored by a plc intelligent control center and has fault warning and linkage control functions. It can flexibly configure modular equipment to meet the diversified application of building materials, rubber products and other fields.

As a professional manufacturer, Kowloon Machinery provide customized tire recycling solution depending on your requirements.

Waste tire recycling system is mainly used for crushing truck tires, car tires, bus tires, OTR tires and various rubber products like belt, seal parts, pipes into rubber granules or rubber powder with required fineness, to realize the recycling and reusing of waste tires. The finished products are used to produce reclaimed rubber, modified asphalt, rubber bricks, pyrolysis oil, sealing strips, insulating rubber materials, waterproof materials, drainage pipes, paving of roads and runways, road coverings, TDF, TDA, etc.

Car Tire

Truck Tire

OTR Tire

Waste Rubber Products

1. Fully automatic solution, the entire system requires only 3 people to complete all on-site operations, high degree of automation and labor saving.

2. The production line is water-cooled and temperature-controlled, operating at room temperature to extend the service life of the equipment.

3. The production line adopts modular design, and equipment is configured according to the customer's production requirements.

4. Advanced technology makes installation, replacement, inspection and maintenance more convenient and safer.

5. We insist on testing each machine before it leaves the factory to ensure good quality and stable performance.

6. CE and ISO certification, unified standards and focus on quality.

For different tire characteristics and productivity requirements, equipment may include:

1. Tire wire drawing machine: remove tire steel wire.

2. Conveying equipment: belt conveyor, screw conveyor and air pressure transmission system.

3. Tire shredder: shreds tires into pieces (50mm-100mm).

4. Tire rasper: separates rubber and steel wire, processes them into rubber particles (10mm-20mm).

5. Magnetic separator: separates steel wire from rubber-steel mixture.

6. Rubber granulator: crushes rubber particles to smaller sizes granules (1mm-7mm).

7. Vibrating screen: sorts rubber granules of different sizes, and oversized granules are sent back for secondary crushing.

8. Fiber separator: removes fibers.

9. Secondary magnetic separator: removes fine steel wire that may remain.

10. Rubber powder making machine: grinds rubber granules into powder (5 mesh-80 mesh).

11. Fully automatic bagging system: pack the finished products into storage bags or packaging bags.

Kowloon Machinery has been committed to the environmental energy recycling. According to different solid waste fields, such as domestic waste, large waste, paper mill waste, waste tires, scrap metals, industrial hazardous waste, biomass waste, agricultural and forestry waste, etc., we provide targeted overall solid waste solutions. Kowloon Machinery's products approved by CE and ISO certificates. Up to now, havs exported to more than 100 countries, with more than 5000 cooperative clients.

Kowloon Machinery pays attention to product quality and after-sales service. From the early technical consultation, equipment selection, and solution design, to the mid-term installation guidance, equipment commissioning, and operation training, to the later remote diagnosis and on-site maintenance, we provide customers with considerate services throughout the process. The professional service team is on call 24 hours a day to ensure that customers receive timely and efficient support and help throughout the entire cycle of equipment use, and solve customers' worries in all aspects.

This is the second step system for waste tire processing after tire wire removal. The whole tire is cut into 50-100mm rubber chips according to the requirements. The rubber chips can be used in Tire Derived Fuel and Tire Derived Aggregate industry.

The wire separation system is used to produce wire-free rubber for use as mulch, crumb rubber and pyrolysis feedstock. The unique design of the tire rasper separates the wire from the shredded tires, allowing processors to get another revenue stream from steels.

The system includes rubber granulator, ladder type air separator and pulse dust removal system. It can process rubber granules into 1-7 mm size. During this process, the majority of the nylon fiber is separated and collected. Rubber crumbs can be used for a variety of products such as rubber tiles, running runways, molded products.

Rubber Powder Making System is the final stage of the tire recycling process. To grind rubber crumbs into fine powder that can be adjusted from 5 to 80 mesh. The grinded material is conveyed into a screening system to get different sizes based on needs. The pure rubber powder can be used for molded rubber products, modified asphalt, synthetic turf infill, etc.