Tub grinder is a large-scale wood crushing equipment with a wide range of uses and high efficiency. It can be used to crush large materials such as tree roots and waste furniture, also suitable for crushing small-diameter wood and board scraps. Widely used for biomass power plant, paper mill, sawdust plant, mechanism charcoal, wood-based board factory, wood crushing and processing base and other industries.

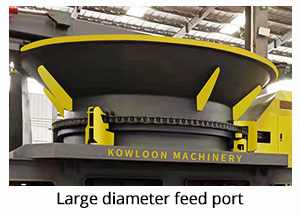

Tub grinder is made of high-strength steel plates precision welded, the structure mainly includes the frame, casing, power system, hydraulic system, electrical system, and the rotating material box driven by the material box drive device. Knife cutting has replaced traditional wood splitting machines and chipping machines. The disc crushing inlet is more than two meters, the material is directly fed by the grab machine, and discharged by folding hydraulics, which makes outdoor mobile operation more convenient.

Kowloon Machinery provide both stationary and mobile type tub grinder according to requirements.

Tube grinder is a professional crushing machine for crushing various tree roots, stumps, and tree knots, also can be used to process all kinds of small wood waste, board, batten, round wood core, log, branch, pallet, building templates, etc.

Tree Roots

Branches

Wood

Pallet

Tree Logs

1. The complete set of equipment adopts automatic control, which an realize remote control, reducing labor costs, while more ensuring the safety of production.

2. Easy maintenance. The hydraulic material box flipping device can achieve a large-angle flip when the machine needs maintenance. Maintenance is very convenient and reduces the use of manpower.

3. Adopts a multi-knife rotor knife roller, and a reasonable arrangement and using can improve the service life of the blade.

4. Advanced technology, the offset feed port and the material-selecting teeth installed on the inner wall of the feed hopper play the role of auxiliary feeding, and the equipment adopts frequency conversion technology. Once the rotor load is too large, the feed hopper will rotate in the opposite direction, so there is no need to worry about the equipment getting stuck.

Kowloon Machinery has been committed to the environmental energy recycling. According to different solid waste fields, such as domestic waste, large waste, paper mill waste, waste tires, scrap metals, industrial hazardous waste, biomass waste, agricultural and forestry waste, etc., we provide targeted overall solid waste solutions. Kowloon Machinery's products approved by CE and ISO certificates. Up to now, havs exported to more than 100 countries, with more than 5000 cooperative clients.

Kowloon Machinery pays attention to product quality and after-sales service. From the early technical consultation, equipment selection, and solution design, to the mid-term installation guidance, equipment commissioning, and operation training, to the later remote diagnosis and on-site maintenance, we provide customers with considerate services throughout the process. The professional service team is on call 24 hours a day to ensure that customers receive timely and efficient support and help throughout the entire cycle of equipment use, and solve customers' worries in all aspects.

|

Model |

Power |

Capacity (t/h) |

Feeding diameter (mm) |

Rotary speed (rpm) |

Blade qty. |

|

JLTG-3600-480 |

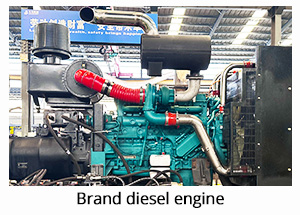

480hp diesel engine, 6 cylinders, fuel consumption 30/liter at full load, 8pcs 825 type tires |

25-45 |

2350 |

960 |

4 (24pcs hammer) |

|

JLTG-3600-530 |

530hp diesel engine, 6 cylinders, fuel consumption 50/liter at full load, 8pcs 825 type tires |

45-60 |

2350 |

960 |

4 (24pcs hammer) |