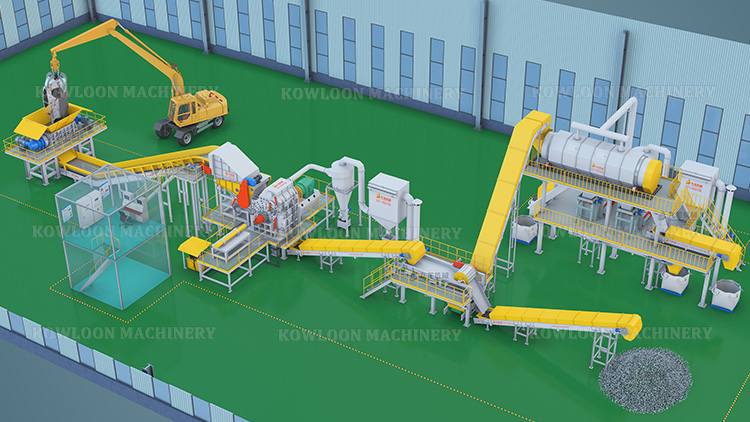

Scrap metal recycling system is designed for shredding and recycling various metal scraps. The system consists of chain plate conveyor, double shaft shredder, metal crusher, drum screen, eddy current separator, etc. It is cost-effective, safe and durable. It is widely used for waste car shell, color steel tiles, metal drums, metal plates, scrap aluminum, scrap steel, scrap iron, keel bars, rolling doors, scrap angle irons, home appliances, etc.

Kowloon Machinery has rich project experience, provide metal recycling line equipment with customized solution depend on your requirement.

√ Scrap steel, iron, copper, aluminum, lead plates and other metal fragments and scraps discarded from the metallurgical industry and metal processing industry.

√ Used car: Car shell, bumper, engine, carriage boards, oil filter, motor, wheels, motorcycle, bike, etc.

√ Home appliances: Refrigerator, air conditioner, washing machine, TV, microwave oven, etc.

√ Metal barrel, paint buckets, beverage cans.

√ Construction and demolition waste: Color steel tiles, rebar, rolling shutters, keel bars, scrap angle iron, bridge aluminum, etc.

Mixed Metal Waste

Used Car

Scrap Steel

Scrap Aluminum

Scrap Iron

Electric Motor

Oil Filter

Home Appliances

Metal Can

Metal Barrel

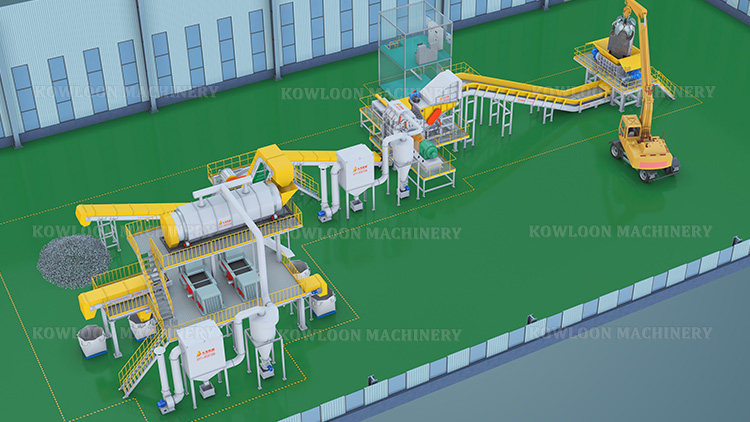

1. The whole line is modularly designed, and each single machine works together efficiently. Customers can flexibly plan the layout according to the production site and needs.

2. Double crushing system, double-shaft shredder cuts scrap metal into small pieces, metal hammer mill removes impurities, strictly controls the size of finished products, and increases stacking density.

3. PLC control system, easy to operate with high automation, effectively reduce labor costs.

4. Deeply sort materials to separate metals from non-metals, with a purity of over 98%, meeting the requirements for resource utilization.

The entire system is shredded by a heavy-duty shredder and then processed by a hammer crusher. During the hammer crushing process, wind equipment is used to remove lightweight materials and dust. Iron containing metals are separated by a strong magnetic device, and non-ferrous metals and plastics are separated by an eddy current separator.

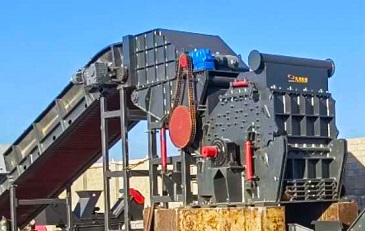

1. Double Shaft Shredder

Metal shredder is a device designed for coarse crushing of large volume, high hardness metals. Relying on the principle of "cutting and shearing", motors drive recucers to transmit torque to the moving rotor. The roller blades chop the metal like scissors, and the crushed material is discharged from the bottom of the equipment.

2. Metal Crusher

Metal crushers can effectively break large materials into small pieces or particles for subsequent recycling, smelting or reuse.

3. Drum Magnetic Separator

When the iron metal flows into the magnetic field through magnetic separation, it is adsorbed on the surface of the drum, and other impurities are taken out of the magnetic field as the drum rotates.

4. Eddy Current Separator

Use the magnetic field force of the conductor transformation to separate the conductor from the non-conductor. The eccentric magnetic pole technology ensures the separation rate and processing volume per unit time.

Metal shredder is mainly used to shred scrap metal and increase its stacking density for easy transportation and recycling. This equipment is widely used to crush various scrap metal materials such as: Car shell, Sheet metal waste, Metal drums, Aluminum can, Thin iron sheets, Punching scrap, Scrap steel, Metal cuttings and shavings, etc.

Metal Crusher is specialized in crushing and recycling scrap metal. It is driven by a high-speed and high-torque motor, the hammer on the rotor of the crusher hits the metal in the crushing chamber in turn. Under strong impact, the metal is torn, hammered, lumped, crushed into small particles.

For different raw materials, our customized solution will help you achieve high purity & high performance metal shredding, sorting and recycling, recover useful materials as cost-effective as possible, maximizes economic benefits.