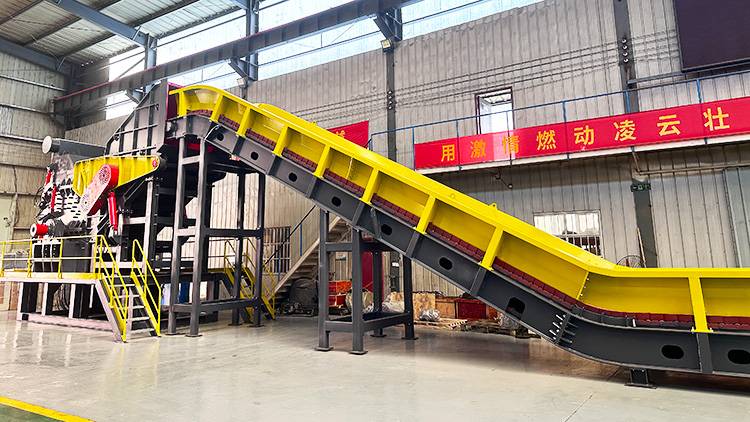

Metal Crusher can effectively break large materials into small pieces or particles for subsequent recycling, smelting or reuse. It is driven by a high-speed and high-torque motor, the hammer on the rotor of the crusher hits the metal in the crushing chamber in turn. Under strong impact, the metal is torn, hammered, lumped, crushed into small particles. The scrap metal hammer crusher can peel off the surface dirt such as rust and paint on the surface of the scrap steel during the crushing process, and then under the action of the magnetic separator, high quality and high purity metal particles can be obtained.

Kowloon Machinery metal crusher can break scrap cars, home appliances, broken bridge aluminum, metal barrels, etc. Widely used in steel plants, metal smelters, metal foundries, scrap metal recycling stations, metal recycling resources companies, metal products factories, metal processing plants, automobile manufacturers, other industries and fields.

√ Metal fragments and scraps discarded by the metallurgical industry and metal processing industry: Scrap steel, iron, copper, aluminium, lead plates, etc.

√ Scrapped cars: Car shell, bumper, engine, carriage boards, oil filter, motor, wheels, motorcycle, bike, etc.

√ Waste home appliances: Refrigerator, air conditioner, washing machine, TV, vacuum cleaner, microwave oven, etc.

√ Metal products: Metal barrel, paint buckets, beverage cans, motor rotors, etc.

√ Construction and demolition waste: Color steel tiles, rebar, rolling shutters, keel bars, scrap angle iron, bridge aluminum, etc.

Scrap Metal

Scrap Car

Home Appliances

Metal Barrel

Metal Can

Motor Rotor

Oil Filter

Scrap Aluminum

Scrap Iron

Scrap Steel

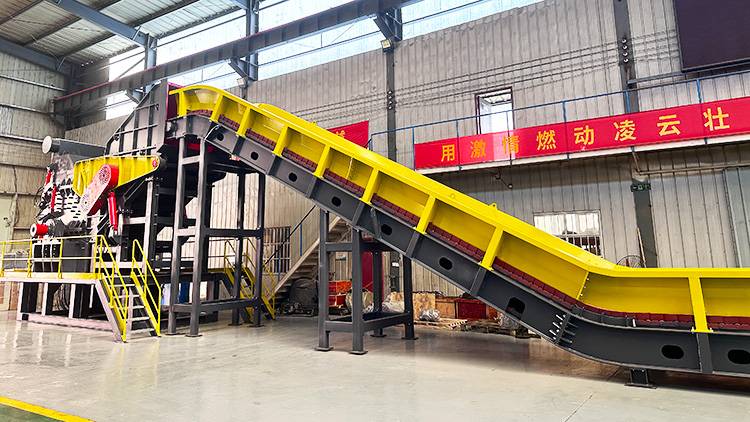

1. Uses an automatic operation cabinet, PLC control, has a high degree of automation.

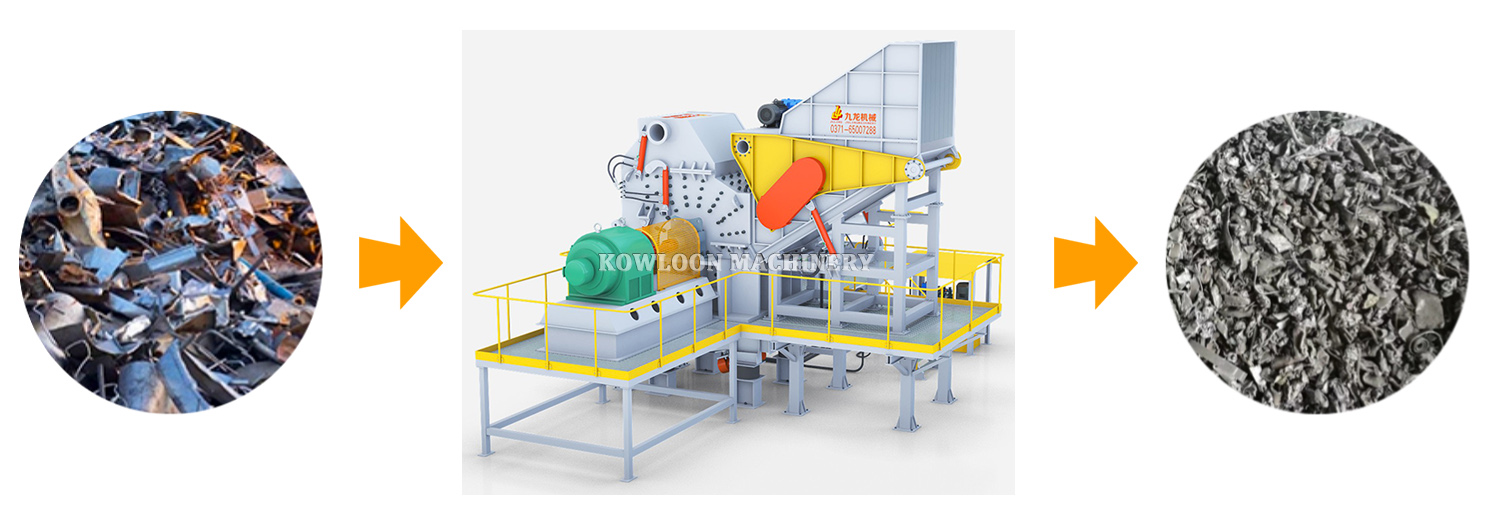

2. The swing hammer and ring hammer are combined, which can crush and knead in one, significantly remove paint and other dirt, and form high-density agglomerated materials, good crushing effect on any high-hardness material.

3. The hydraulic cylinder cover opening device saves time, labor and effort for maintenance.

4. The hydraulic feeding device pre-compresses the material, expands the feeding range and improves production efficiency.

5. The unique chiseling plate design applies secondary shear force to the material.

6. Strong structure, the main body of the equipment is made of thickened steel plate, and the lining is made of high manganese cast iron, to ensure the strength of the equipment.

7. Safety door is set up so that the unbreakable materials can be discharged from the crushing chamber to avoid damage to the crusher.

8. Installed in a foundation, the running is stable and reliable, large torque, high output, low noise and wear resistance.

Kowloon Machinery has 19 years of technology accumulation and specializes in the production of solid waste recycling equipment, such as biomass waste, waste tires, scrap metals, large waste, industrial waste, agricultural and forestry waste, etc., and provides targeted recycling solutions. Our products have obtained multiple patents and CE, ISO certifications. At present, our solid waste recycling projects cover Poland, Czech Republic, Romania, Russia, South Africa, Algeria, Brazil, Saudi Arabia and many other countries.

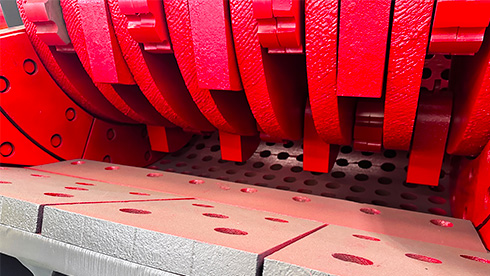

|

Model |

JLHC-200 |

JLHC-315——420HP |

JLHC-450——600HP |

|

Thickness of case plate |

30mm |

40mm |

50mm |

|

Thickness of screen |

60mm, material: cast steel, mesh 65*85mm |

100mm, material: cast steel, mesh 65*85mm |

100mm, material: cast steel, mesh 65*85mm |

|

Thickness of edge lining plate |

40mm |

50mm |

60mm |

|

Main shaft Diameter |

200mm,material:40Cr |

250mm,material:40cr |

280mm,material:40cr |

|

Rotor disc |

φ800mm, thickness 50mm, welding wear layer |

φ900mm, thickness 60mm, welding wear layer |

φ1200mm, thickness 80mm, welding wear layer |

|

Hammer |

10pcs, material: 13Cr2Mn, unit weight: 35KG |

10pcs, material: 13Cr2Mn, unit weight: 45KG |

14pcs, material: 13Cr2Mn, unit weight: 75KG |

|

Thickness of Forced feed plate |

16mm, hydraulic system |

20mm, hydraulic system |

20mm, hydraulic system |

|

Motor/control cabinet |

8P-200kw (1pcs), brand: WNM Soft starting cabinet, electrical components: Chint/Delixi |

8P-315kw (1pcs), brand: Simo - Slip Ring motorcyclo motor Water-resistant starting cabinet, electrical components: Chint/Delixi |

8P-450kw (1pcs), brand: Simo - Slip Ring motorcyclo motor Water-resistant starting cabinet, electrical components: Chint/Delixi |

|

Feed chain conveyor |

9000*1200mm,1pcs, power:7.5KW |

12000*1400mm,1pcs, power:11KW |

12000*1600mm,1pcs, power:11KW |

|

Vibrating discharge machine |

2500*1000mm,1pcs, power:3KW |

2500*1000mm,1pcs, power:3KW |

3000*1200mm,1pcs, power:4KW |

|

Discharge conveyor |

1000*6000mm,1pcs, power:4KW |

1000*6000mm,1pcs, power:4KW |

1000*6000mm,1pcs, power: 4KW |

|

Magnetic separation vibration feeder |

2000*1000mm,1pcs, power: 3KW |

2000*1200mm,1pcs, power: 4KW |

2000*1200mm,1pcs, power: 4KW |

|

Drum magnetic separator |

1000*650mm1pcs, power: 5.5KW |

800*1000mm 1pcs, power: 7.5KW |

1000*1000mm1pcs, power: 7.5KW |

|

output conveyor |

800*8000mm1pcs, power: 4kw |

800*8000mm1pcs, power: 4KW |

1000*8000mm1pcs, power: 5.5KW |

|

Slag removal conveyor |

500*8000mm1pcs, power: 3kw |

600*8000mm1pcs, power: 3KW |

650*8000mm1pcs, power: 4KW |

|

DMC-120 Filter bag type dust collector/Cyclone/pipe/fan |

1set power: 7.5KW |

1set power: 11KW |

1set power: 22KW |

|

Capacity |

4-6t/h |

8-10t/h |

10-15t/h |