Dust-free hammer grinder has the characteristics of high quality, good performance, high efficiency and energy saving, and wide application. It is a must-chosen machine in some recycling production lines. It can effectively reduce dust pollution and comply with modern environmental protection concepts. It consists of a pulverization chamber, screen mesh, shell, base, pulley, induced draft fan, etc. The pulverization fineness can be adjusted according to the screen mesh.

The hammer grinder can handle a wide range of materials such as wood scraps, wood templates, bamboo, paper, corn straw, coconut huks, twigs, plastics, textile shreds, etc. The grinded materials are widely used as basic raw material of making paper, particleboard, fiberboard, non wood-based board and pulping paper making.

√ Wood waste: trees, logs, branches, bamboo, wood chips, wood board, pallet, wood scraps, wood templates, etc.

√ Biomass waste: rice straw, wheat straw, paddy straw, corn stalks, sugarcane, grass, forages, reed, coconut shell, cotton stalks, etc.

√ Other waste: cardboard, Chinese herbal medicines, textile shreds, etc.

Bamboo

Branches

Straw

Cardboard

Treen Logs

Coconut Shell

Wood Waste

Corn Stalks

Sugarcane

Textile Waste

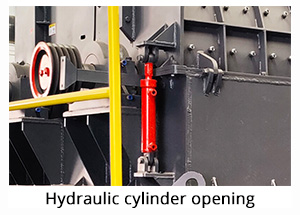

1. The grinding chamber can be opened by hydraulic, easy to maintain and replace hammers.

2. Enclosed design, equipped with pulse dust collector and discharge by enclosed screw conveyor, to ensure working in low dust condition, workable inside workshop.

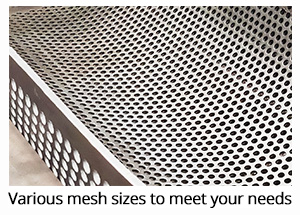

3. Screen mesh size is customized for different requirements on size of end product.

Kowloon Machinery has been committed to the environmental energy recycling. According to different solid waste fields, such as domestic waste, large waste, paper mill waste, waste tires, scrap metals, industrial hazardous waste, biomass waste, agricultural and forestry waste, etc., we provide targeted overall solid waste solutions. Kowloon Machinery's products approved by CE and ISO certificates. Up to now, havs exported to more than 100 countries, with more than 5000 cooperative clients.

Kowloon Machinery pays attention to product quality and after-sales service. From the early technical consultation, equipment selection, and solution design, to the mid-term installation guidance, equipment commissioning, and operation training, to the later remote diagnosis and on-site maintenance, we provide customers with considerate services throughout the process. The professional service team is on call 24 hours a day to ensure that customers receive timely and efficient support and help throughout the entire cycle of equipment use, and solve customers' worries in all aspects.

|

Model |

JLSD1500 |

|

Infeed port size |

1468*450mm |

|

Hammer blade |

66pcs, made of 65Mn |

|

Liner plate |

M13Cr2, 42pcs |

|

Output material size |

3-30mm (screen customizable) |

|

Main motor |

75kw+75kw |

|

Discharging conveyor motor |

11kw |

|

Feeding conveyor motor |

4kw |

|

Hydraulic motor |

2.2kw |

|

Output screw conveyor |

Dia.273mm x 1, motor 7.5kwx1 |

|

Dust collector |

48-bag pulse dust collector,4kw |

|

Cyclone |

With air-lock valve, fan 7.5kw |

|

Dimension |

3150*3250*3350mm |

|

Weight |

5500kg |