Double shaft shredder is a powerful equipment that can crush large, difficult-to-shred or hard-to-transport materials into small pieces by shearing, squeezing and tearing, to meet the shredding requirements. It has the characteristics of low speed, high torque, strong power, good stability, adjustable discharging particle size, wear resistance, strong load-bearing capacity, easy operation, cost reduction and efficiency improvement.

Kowloon Double shaft shredder is mainly composed of blade spindle, fixed knife, carrying box, box bracket, feeding system, hydraulic pushing system, power system, and electrical control system. Adopts an advanced PLC detection control system, which is equipped with start, stop, reverse and overload automatic reverse control functions. It has the characteristics of low energy consumption, large processing capacity, high torque, low noise, and low maintenance cost, and is suitable for crushing and processing over a hundred types of waste.

√ Scrap Metal: iron, steel, aluminum, copper and other metal plates, metal barrel, cans and castings, car, motorcycles, engine, oil filters, motor, color steel tiles, construction and demolition waste, etc.

√ Wood Waste: tree, logs, branches, root, bark, pallets, wooden board, timber, lumber, etc.

√ Biomass: rice straw, wheat straw, corn stalks, sorghum stalks, sugarcane, corn cob, palm leaves, EFB, coconut shells, rhizome, etc.

√ Cardboard: waste carton, OCC (old corrugated cardboard), paper mill waste and pulper ropes, etc.

√ Plastic: PVC, PE, PP, ABS, PET, HDPE and other plastic waste, pipes, bottles, barrels, pallet, engineering plastics, etc.

√ Home Appliances: Fridge, TV, monitors, microwave ovens, washers and other small and medium-sized home appliances shell, electrical equipment, etc.

√ Furniture: sofas, mattresses, tables, cabinets, etc.

√ Rubber: car tires, truck tires, OTR tires, conveyor belt, rubber pipes, rubber products, etc.

√ Electronic waste: computer host shell, hard drive, phone, etc.

√ Other waste: sponge, leather, fabric, garbage, household waste and so on.

Scrap Metal

Used Car

Used Furniture

Wood Waste

Biomass Waste

Plastic Waste

Household Waste

Green Waste

Fabric Waste

Waste Cardboard

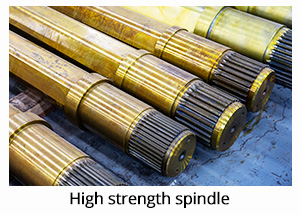

1. Low speed, high torque rotor, crushing efficiency improve significantly, suitable for both soft and hard materials.

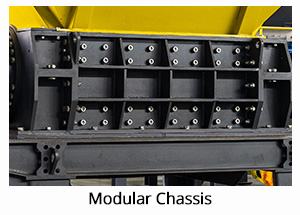

2. Large chassis, high safety level, ultra-large capacity, sturdy and reliable, strong impact resistance.

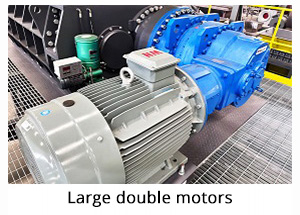

3. High performance well-known motors and reducers are available for different customers options, driving force is stable.

4. Overload reversing function, stop, forward rotation are set on the cabinet controller, minimizing blades damages.

5. Individual electrical control panel with PLC control system ensure the machine work properly and safety.

6. Alloy cutting blade, imported material, high strength and good wear resistance, easy replacement and maintenance.

Kowloon Machinery has been committed to the environmental energy recycling. According to different solid waste fields, such as domestic waste, large waste, paper mill waste, waste tires, scrap metals, industrial hazardous waste, biomass waste, agricultural and forestry waste, etc., we provide targeted overall solid waste solutions. Kowloon Machinery's products approved by CE and ISO certificates. Up to now, havs exported to more than 100 countries, with more than 5000 cooperative clients.

Kowloon Machinery pays attention to product quality and after-sales service. From the early technical consultation, equipment selection, and solution design, to the mid-term installation guidance, equipment commissioning, and operation training, to the later remote diagnosis and on-site maintenance, we provide customers with considerate services throughout the process. The professional service team is on call 24 hours a day to ensure that customers receive timely and efficient support and help throughout the entire cycle of equipment use, and solve customers' worries in all aspects.

|

Model |

JLSS600 |

JLSS1000 |

JLSS1200 |

JLSS1500 |

JLSS2000 |

JLSS2600 |

|

Main shaft power |

4-15kw*2 |

4-30kw*2 |

4-37kw*2 |

4-45kw*2 |

4-90kw*2 |

4-160kw*2 |

|

Main shafe rotary speed |

18-20rpm |

18-20rpm |

18-20rpm |

18-20rpm |

18-20rpm |

18-20rpm |

|

Working capacity |

2-5t/h |

5-10t/h |

6-15t/h |

8-18t/h |

10-25t/h |

25-60t/h |

|

Weight |

3000kg |

5000kg |

6000kg |

12000kg |

15000kg |

36000kg |

|

Conveyor motor power |

None |

None |

None |

4-3KW |

4-3kw |

4-3KW |

|

Number of cutter head |

20pcs*φ400 |

34pcs*φ400 |

42pcs*φ400 |

46pcs*φ550 |

50pcs*φ600 |

40pcs*φ720 |

|

Finished ships size |

3-10cm |

3-10cm |

3-10cm |

3-10cm |

3-10cm |

3-10cm |

|

Feeding tank size |

0.82*0.9m |

1.2*1m |

1.4*1m |

2*2m |

2.3*2m |

2.5*1.4m |

|

Dimension |

2.6*2*1.9m |

3*2*1.9m |

3.2*2*1.9m |

4*1.7*2.4m |

8*2.5*2.4m |

8.2*4.4*4.3m |