Waste paper dry pulping equipment is a special equipment for recycling waste cardboard for repeated papermaking, which can greatly save resources and reduce pollutant emissions. Its unique design concept and processing technology can quickly process any shape of old corrugated cardboard, hard paper, newspapers, waste books, cartons, paper tubes, kraft paper and other materials into small pieces, recycling paper fibers in waste paper and baling. It is mainly used in biomass power plants, paper mills, waste paper recycling industries, etc.

Kowloon Machinery provide custom cardboard recycling solution according to your production requirements.

All kinds of waste paper, cartons, newspapers, kraft paper, OCC (old corrugated cardboard), paper factory waste and pulper ropes, etc.

OCC Cardboard

Kraft Paper

Newspaper

Pulper Ropes

1. The equipment uses imported alloy blades, planetary reducers and other brand configurations to ensure long-term stable operation of the equipment.

2. The system integrates software and hardware, adopts modular design, and covers crushing, sorting, and dust removal systems.

3. The full set is equipped with PLC control system and visual control system to monitor the operation status of the equipment in real time.

4. The production line layout is compact and reasonable, which can run uninterruptedly for a long time, effectively reducing the operation cost.

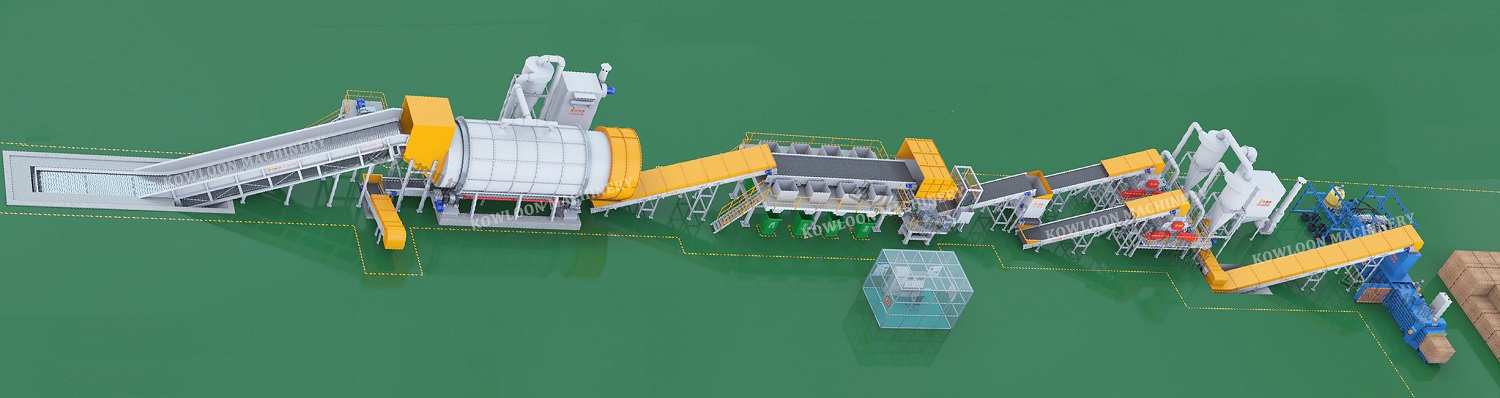

The waste paper dry pulping system uses a chain plate conveyor to feed the waste paper into a unpacking machine, then through a belt conveyor to a sorting platform where workers sort out waste plastics, stones, and other debris. The waste cardboard is shredded by a shredder and then enters the buffer material bin. The discharge conveyor is equipped with an iron remover to remove iron impurities. The waste paper enters the intelligent composite waste paper pulping machine, and the finished paper fibers are discharged from a specially designed screen and packaged. The dry pulping system is equipped with a water resistance water mist spray device and a PLC control system to monitor the equipment status in real time and ensure stable operation.

Kowloon Machinery has 19 years of technology accumulation and specializes in the production of solid waste recycling equipment, such as biomass waste, waste tires, scrap metals, OCC paper, large waste, industrial waste, agricultural and forestry waste, etc., and provides targeted recycling solutions. Our products have obtained multiple patents and CE, ISO certifications. At present, our solid waste recycling projects cover Poland, Czech Republic, Romania, Russia, South Africa, Algeria, Brazil, Saudi Arabia and many other countries.

Waste paper dry pulping equipment is used in paper mill processing. It is suitable for tearing and crushing various waste papers and cardboard, with large processing capacity, low energy consumption, stable and reliable.

The system includes crushing, sorting, packaging, dust removal system, etc. The chain plate conveyor transports the twisted rope to coarse shredder, where it is crushed into small sizes. The iron metal is sorted out by magnetic separator, and then finely crushed by a fine grinder before entering the packaging machine. The entire line is equipped with dust reduction system, which does not produce secondary pollution.