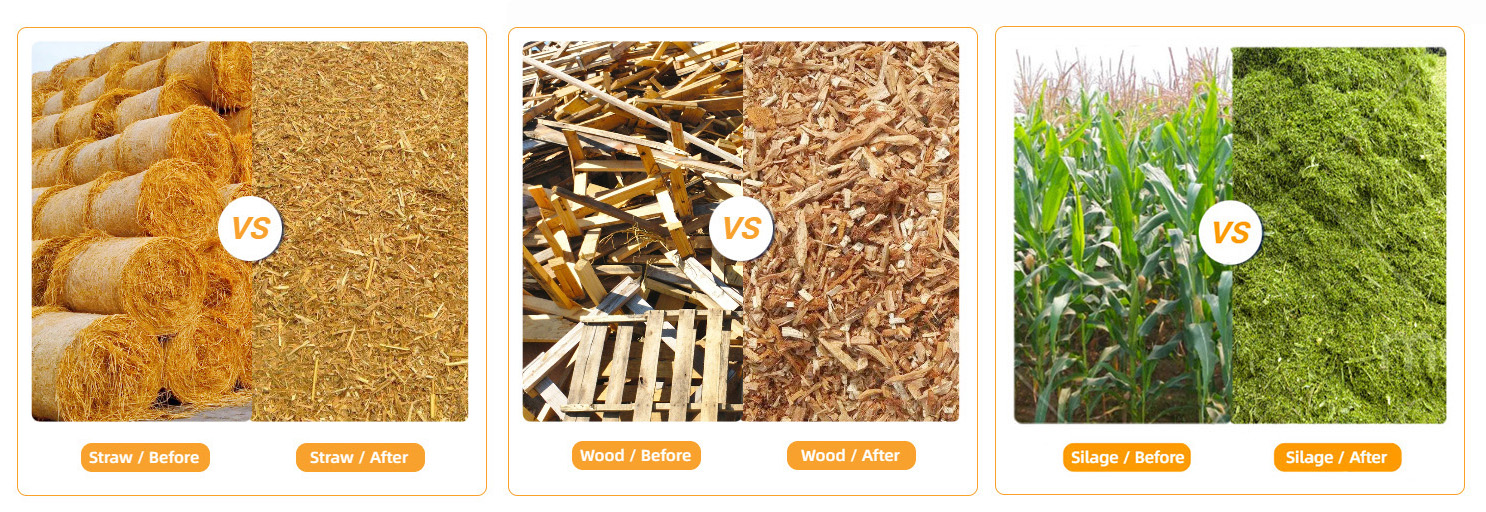

Biomass shredder is a specialized mechanical equipment used for processing agricultural waste such as rice straw, paddy straw, wheat straw. Biomass shredder achieves efficient and precise processing of materials such as straw, through the working principle of biaxial shearing and extrusion. The crushed material can be used as livestock forage and papermaking raw materials, as fuel for boiler, furnace or power plant.

Kowloon Machinery supply biomass recycling system with customized solution depend on your requirement.

Biomass waste such as rice straw, wheat straw, paddy straw, corn stalks, peanut stalks, wheat stalks, soybean stalks, cotton stalks, sugar cane, bark, corn cob, palm leaves, EFB, coconut shells, rhizome, wooden boards, etc.

Straw

Dry Corn Stalks

Grass Bales

Soybean Stalks

Cotton Stalks

Coconut Leaves

Coconut Shell

Palm EFB

Wood Waste

Green Waste

1. Tungsten carbide wear-resistant tools can effectively increase production and extend service life through laser cladding. Tools can also be repaired multiple times after wear, saving use costs.

2. Modular chassis. The chassis adopts mortise and tenon design and overall annealing process. Prestress caused by welding is avoided, and the mechanical strength of the chassis is high. The chassis is divided into upper and lower parts, which is convenient and quick to inspect and maintain.

3. The use of planetary reducers can reduce the motor speed and increase the output torque. It has many advantages such as light weight, small size, high transmission efficiency, wide reduction range, high precision and low noise.

Kowloon Machinery has been committed to the environmental energy recycling. According to different solid waste fields, such as domestic waste, large waste, paper mill waste, waste tires, scrap metals, industrial hazardous waste, biomass waste, agricultural and forestry waste, etc., we provide targeted overall solid waste solutions. Kowloon Machinery's products approved by CE and ISO certificates. Up to now, havs exported to more than 100 countries, with more than 5000 cooperative clients.

Kowloon Machinery pays attention to product quality and after-sales service. From the early technical consultation, equipment selection, and solution design, to the mid-term installation guidance, equipment commissioning, and operation training, to the later remote diagnosis and on-site maintenance, we provide customers with considerate services throughout the process. The professional service team is on call 24 hours a day to ensure that customers receive timely and efficient support and help throughout the entire cycle of equipment use, and solve customers' worries in all aspects.

|

Model |

JLSS600 |

JLSS1000 |

JLSS1200 |

JLSS1500 |

JLSS2000 |

JLSS2600 |

|

Main shaft power |

4-15kw*2 |

4-30kw*2 |

4-37kw*2 |

4-45kw*2 |

4-90kw*2 |

4-160kw*2 |

|

Main shafe rotary speed |

18-20rpm |

18-20rpm |

18-20rpm |

18-20rpm |

18-20rpm |

18-20rpm |

|

Working capacity |

2-5t/h |

5-10t/h |

6-15t/h |

8-18t/h |

10-25t/h |

25-60t/h |

|

Weight |

3000kg |

5000kg |

6000kg |

12000kg |

15000kg |

36000kg |

|

Conveyor motor power |

None |

None |

None |

4-3KW |

4-3kw |

4-3KW |

|

Number of cutter head |

20pcs*φ400 |

34pcs*φ400 |

42pcs*φ400 |

46pcs*φ550 |

50pcs*φ600 |

40pcs*φ720 |

|

Finished ships size |

3-10cm |

3-10cm |

3-10cm |

3-10cm |

3-10cm |

3-10cm |

|

Feeding tank size |

0.82*0.9m |

1.2*1m |

1.4*1m |

2*2m |

2.3*2m |

2.5*1.4m |

|

Dimension |

2.6*2*1.9m |

3*2*1.9m |

3.2*2*1.9m |

4*1.7*2.4m |

8*2.5*2.4m |

8.2*4.4*4.3m |